JS Series

Twin Shaft Concrete Mixer

Double-shaft forced mixer for concrete batching plants

- Discharge Capacity 1.5 – 4.5 m³ / batch

- Drive Technology Multi-motor synchronization for heavy-load stability

The standard twin-shaft compulsory concrete mixer is an advanced concrete mixing machine independently developed by the company. It adopts a dual-motor configuration with dual angular planetary gear reducers driving two horizontally arranged mixing shafts to rotate in opposite directions. Cross-arranged mixing blades on the shafts generate rolling and convective material movement, achieving intensive and uniform mixing.

With dual planetary reducer transmission, the mixer operates smoothly and delivers high output torque. It features strong mixing capacity, excellent mixing quality, high reliability, and low noise. The JS series mixer is widely used in high-speed railway construction, highway projects, hydropower stations, airport construction, and ready-mix concrete plants.

Technical Parameters

| Parameter/Model | |

|

|

|

|

|

| Charging capacity (L) | 1875 | 2250 | 3000 | 4500 | 6000 | 6750 |

| Discharging capacity (L) | 1250 | 1500 | 2000 | 3000 | 4000 | 4500 |

| Theoretical capacity (m³/h) | 75 | 90 | 120 | 180 | 240 | 270 |

| Mixing motor power (kW) | 2×22 | 2×30 | 2×37 | 2×55 | 2×75 | 2×75 |

| Lubrication pump motor power (kW) | 0.09 | 0.09 | 0.09 | 0.09 | 0.09 | 0.09 |

| Hydraulic system motor power (kW) | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 |

| Solenoid valve power supply (V) | DC24 | DC24 | DC24 | DC24 | DC24 | DC24 |

| Number of mixing arms | 16 | 12 | 16 | 18 | 22 | 22 |

| Max. aggregate size (mm) | 80 | 80 | 80 | 80 | 80 | 80 |

| Overall dimensions (L×W×H) (mm) | 3000 2750 2000 |

2900 3000 2150 |

3450 3000 2250 |

3900 3300 2230 |

4500 3300 2230 |

4700 3300 2230 |

| Transport dimensions (L×W×H) (mm) | 3000 2000 2000 |

2900 2320 2150 |

3450 2320 2250 |

3900 2600 2230 |

4500 2600 2230 |

4700 2600 2230 |

| Total weight (kg) | 5200 | 6200 | 7500 | 9600 | 11800 | 12300 |

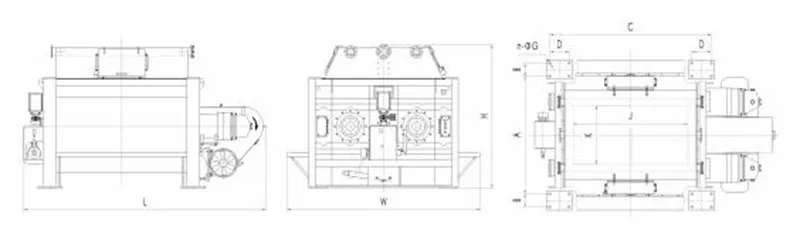

Dimensions

| Model | A | B | C | D | N | G | L | W | H | J | K |

| JS1250 | 1440 | 235 | 1824 | 220 | 16 | 22 | 3000 | 2750 | 2000 | 1330 | 790 |

| JS1500 | 1820 | 200 | 1822 | ... | 8 | 32 | 2900 | 3000 | 2150 | 1120 | 910 |

| JS2000 | 1820 | 200 | 2250 | ... | 8 | 32 | 3450 | 3000 | 2250 | 1460 | 885 |

| JS3000 | 1820 | 200 | 2615 | 300 | 16 | 32 | 3900 | 3300 | 2230 | 1840 | 990 |

| JS4000 | 1820 | 200 | 3065 | 300 | 16 | 32 | 4500 | 3300 | 2240 | 2250 | 970 |

| JS4500 | 1820 | 200 | 3265 | 300 | 16 | 32 | 4700 | 3300 | 2240 | 2430 | 970 |

Features

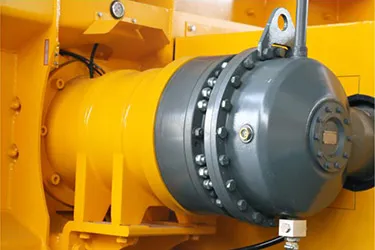

Dedicated Gear Reducer

The concrete mixer is equipped with high-performance angular planetary gear reducer. It is manufactured from high-quality steel using precision CNC machining, with all gears ground to achieve accuracy of Grade 6 or above.

Monitoring System

An optional mixer monitoring system provides real-time monitoring of hydraulic pump and reducer oil temperature and oil level. The system offers on-screen information display, audible and visual alarms, operation records, and alarm history storage. Operators can check running time, discharge cycles, and other operating parameters, and perform maintenance based on system prompts. Multiple intelligent lubrication modes enable automatic lubrication of shaft-end seals.

Lubrication System

The lubrication system utilizes automatically controlled electric lubrication pump. Four pump outlets supply oil to four shaft ends, significantly improving shaft-end sealing performance and service life while minimizing lubricant consumption.

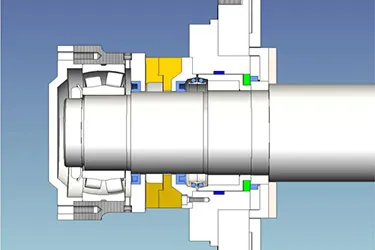

Shaft-End Sealing

Multiple sealing structures combined with oil-pressure sealing technology are used at the shaft ends. Key components are made of special wear-resistant materials to effectively extend service life.

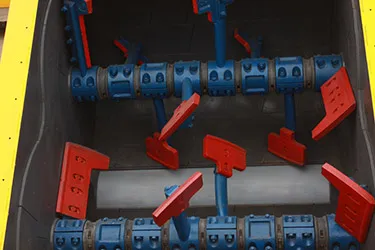

Mixing System

The mixing system adopts a multi-blade design with no dead zones, achieving uniform mixing within a short time. Mixing blades and liners are made of in-house high-chromium alloy wear-resistant cast iron, offering high hardness and excellent wear resistance.

Hydraulic System

An advanced hydraulic system controls the discharge gate. On sudden power failure, a manual pump can be used for emergency discharge to prevent concrete hardening inside the mixer.

Water Supply System

Sprayed water is used for mixing and for cleaning mixing shafts, blades, and shaft ends, preventing material buildup and protecting shaft-end seals. A multi-pipeline water spraying design ensures rapid and uniform water distribution.

Safety Switches

A contact limit switch is installed on the top cover inspection door. When the door is opened, the main motor stops automatically to protect maintenance personnel. A key-operated safety switch is also provided on the mixer body for emergency stop and maintenance. Removing the key prevents accidental operation.

Established in 1991, Jin Rui is a professional concrete plant manufacturer with over 30 years of industry experience. From stationary concrete plants to integrated concrete plants, our concrete equipment serves various construction projects of high-speed railways, bridges, and airports, delivering reliable concrete production solutions tailored to different construction cycles and site conditions.

Get professional advice for your project - contact our experts today.