JN Series

Planetary Concrete Mixer, Multi-Drive

Vertical shaft mixer for concrete batching plants

- Discharge Capacity 1.5 – 4.5 m³ / batch

- Drive System Multi-motor gearbox for redundant, high-torque operation

Our JN series planetary concrete mixers are built for the most demanding concrete production cycles. By utilizing multiple motor drives for a smooth start and high reliability in large-volume concrete batching, this planetary mixer is ideal for precast concrete production such as PC components, pipe piles and masonry blocks.

- Equipped with a hydraulic door opening system that ensures smooth opening and closing with high thrust to prevent material jamming. Depending on actual production need, up to three discharge doors can be configured

- Features a patented adjustable discharge door design that provides excellent sealing and significantly reduces wear on the sealing strips

- Uses a planetary mixing motion (combining revolution and rotation) to ensure more uniform material mixing. The transmission system is designed without the risk of slurry leakage at the shaft end

Technical Parameters

| Model | |

|

|

|

|

| Feed capacity (L) | 3000 | 4500 | 6000 | 6750 | 7500 |

| Discharge capacity (L) | 2000 | 3000 | 4000 | 4500 | 5000 |

| Theoretical productivity (m³/h) | 120 | 180 | 240 | 270 | 300 |

| Mixing motor power (kW) | 2x45 | 3x37 | 3x55 | 3x65 | 3x75 |

| Max. aggregate size (mm) | ≤80 | ≤80 | ≤80 | ≤80 | ≤80 |

| Number of mixing blades | 3x2 | 3x2 | 3x2/3x3 | 3x2/3x3 | 3x2/3x3 |

| Number of scrapers | 3 | 3 | 3 | 3 | 3 |

| Overall dimensions (L×W×H, mm, double door) | 3600x3150x 2430 | 4200x3650×2570 | 4780x4160×2750 | 4780x4160 x2750 | 5350x4460 x2900 |

| Machine weight (kg) | 12300 | 15500 | 20900 | 21300 | 25800 |

Main Components

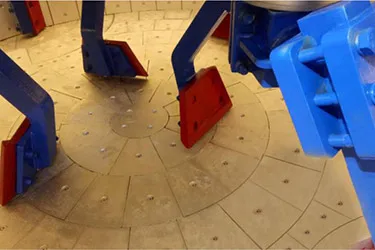

Transmission System

The vertical shaft planetary mixer adopts a multi-motor drive system, ensuring smooth start-up and high reliability. A patented angular transmission gearbox combined with a horizontally mounted motor drive structure simplifies maintenance and reduces the overall mixer height, facilitating transportation, installation, and feeding system arrangement.

The mixer is equipped with a high-performance angular planetary gearbox manufactured from high-quality steel with fully ground gears, achieving accuracy grade 6 or above. The spiral bevel gear input shafts are interchangeable without pairing selection. An external planetary gearbox input system allows maintenance without removing the top cover, making inspection and replacement more convenient. The planetary mixing system uses patented spline quick-release structures for gears and shafts, enabling easy disassembly and maintenance without removing the revolving body.

Monitoring System

An optional mixer monitoring system provides real-time monitoring of hydraulic pump and reducer oil temperature and oil level. The system offers on-screen information display, audible and visual alarms, operation records, and alarm history storage. Operators can check running time, discharge cycles, and other operating parameters, and perform maintenance based on system prompts. Multiple intelligent lubrication modes enable automatic lubrication of shaft-end seals.

Mixing System

Wear parts of the mixing system are made of wear-resistant high-chromium alloy cast iron, significantly extending service life.

Discharge Gates

A patented adjustable discharge gate design provides excellent sealing performance while reducing seal wear. The hydraulic discharge system allows smooth operation, with up to three discharge gates available according to requirements. Manual discharge is supported in emergency situations to prevent material solidification.

Safety Switches

A contact limit switch is installed on the top cover inspection door. When the door is opened, the main motor stops automatically to protect maintenance personnel. A key-operated safety switch is also provided on the mixer body for emergency stop and maintenance. Removing the key prevents accidental operation.

Water Supply System

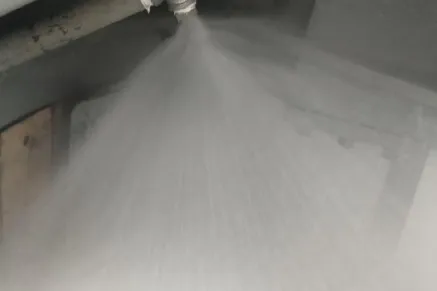

The water supply system uses multi-angle spray nozzles to ensure uniform water distribution, enabling faster and more uniform mixing.

Established in 1991, Jin Rui is a professional concrete plant manufacturer with over 30 years of industry experience. From stationary concrete plants to integrated concrete plants, our concrete equipment serves various construction projects of high-speed railways, bridges, and airports, delivering reliable concrete production solutions tailored to different construction cycles and site conditions.

Get professional advice for your project - contact our experts today.