HZS Series

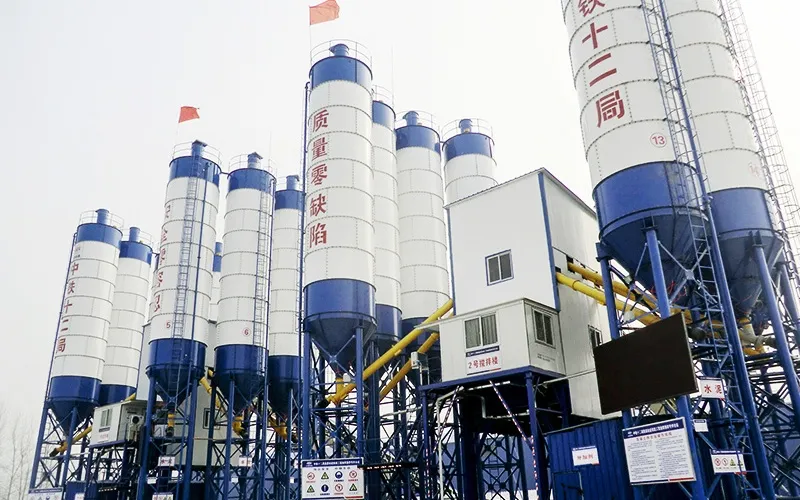

Stationary Concrete Plant

Concrete batch plant configured with twin shaft concrete mixer and belt conveyor for infrastructure and large-scale public projects

- Production Capacity 60–270 m³/h

- Plant Configuration Stationary batching plant with belt conveyor feeding

The HZS series concrete batching plant is engineered for high-performance production, powered by a robust JS Series twin-shaft forced mixer that delivers superior cycle times. By integrating world-class components from industry leaders such as Schneider, AirTAC, and ZEMIC, the batching plant ensures unmatched reliability and operational longevity in the most demanding environments.

Its sophisticated PLC-based control system provides fully automated management with real-time computer tracking, allowing for a precisely controlled feeding sequence that maximizes both mixing performance and production efficiency.

Designed with a modular structural framework for rapid installation and seamless relocation, the concrete batch plant serves as the premier turnkey solution for critical medium-to-large-scale projects, including high-speed railways, highways, hydropower stations, and international airports.

Technical Parameter

|

Model |

|

|

|

|

|

|

|

|

Theoretical capacity (m³/h) |

60 |

75 |

90 |

120 |

180 |

240 |

270 |

|

Mixer model |

JS1000A |

JS1250B |

JS1500B |

JS2000B |

JS3000B |

JS4000B |

JS4500B |

|

Aggregate batching machine model |

HP1600A/J |

HP2000A |

HP2400A |

HP3200B |

HP4800C |

HP6400B |

HP7200B |

|

Single bin capacity of batching machine (m³) |

6/8 |

8/10 |

12/14 |

17 |

22 |

30 |

32 |

|

Belt conveyor capacity (t/h) |

250 |

300 |

400 |

500 |

700 |

800 |

800 |

|

Screw conveyor model |

LSY219 |

LSY219 |

LSY219/ |

LSY219/ |

LSY219/ |

LSY219/ |

LSY219/ |

|

Cement bin capacity |

100T/ 150T/ 200T/ 300T optional |

||||||

|

Aggregate weighing accuracy |

±2% |

±2% |

±2% |

±2% |

±2% |

±2% |

±2% |

|

Cement weighing accuracy |

±1% |

±1% |

±1% |

±1% |

±1% |

±1% |

±1% |

|

Fly ash weighing accuracy |

±1% |

±1% |

±1% |

±1% |

±1% |

±1% |

±1% |

|

Mineral powder weighing accuracy |

±1% |

±1% |

±1% |

±1% |

±1% |

±1% |

±1% |

|

Water weighing accuracy |

±1% |

±1% |

±1% |

±1% |

±1% |

±1% |

±1% |

|

Admixture weighing accuracy |

±1% |

±1% |

±1% |

±1% |

±1% |

±1% |

±1% |

|

Approx. total power (kW) |

80 |

100 |

135 |

170 |

220 |

280 |

280 |

|

Discharge height (m) |

4.1 |

4.1 |

4.1 |

4.1 |

4.2 |

4.2 |

4.2 |

Notes:

- The quantity and capacity of aggregate bins and cement bins are fully customizable. Weighing systems can be configured for either cumulative or individual measurement based on project requirements.

- Total power consumption ratings exclude the power requirements of screw conveyors.

- Standard discharge height is measured from the outlet of the discharge hopper.

- Specifications are subject to optimization and may change without prior notice. Please consult the latest product documentation for finalized data.

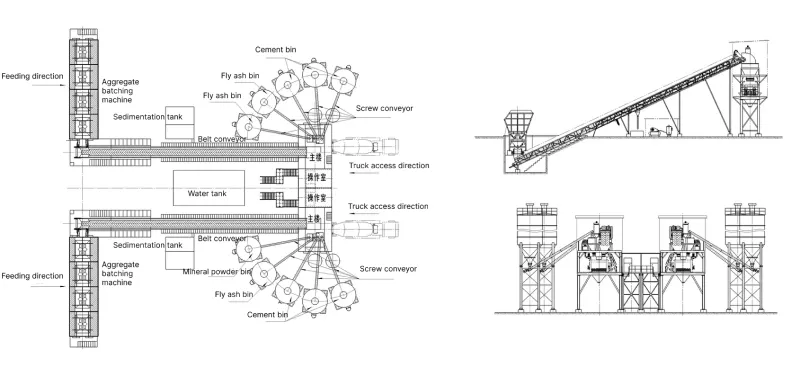

Process Flow

Main Components

Concrete Mixer

Equipped with JS series standard twin-shaft concrete mixer, featuring fast mixing speed, high homogeneity, and stable, reliable performance.

Aggregate Batching Machine

HP series aggregate batching machines feature a modular panel assembly for the bin sections for easy installation. Pneumatic batching ensures fast and accurate dosing, while belt discharge enables clean and rapid unloading. Both cumulative and individual weighing types are available to meet different batching requirements.

Belt Conveyor

The belt conveyor system is designed for high-capacity aggregate feeding and continuous operation. It features a stable structure with deviation monitoring to ensure safe and reliable material transport under heavy-duty working conditions.

Screw Conveyor

The cement screw conveyor features a housing made of high-quality steel pipes. Each section is connected by flanges. The conveying screw adopts a variable-pitch blade design, allowing smooth and stable powder material conveying.

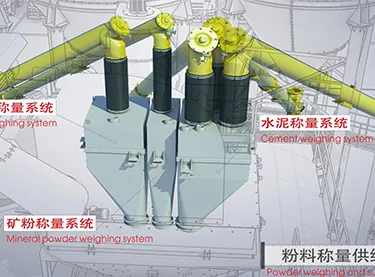

Weighing System

The weighing system is equipped with high-precision load cells to ensure consistent and accurate measurement.

For material release, it utilizes pneumatically operated butterfly valves of premium quality, providing rapid actuation and a hermetic seal to prevent leakage.

Main Tower

The main tower adopts a modular and sectional structural design, making transportation and installation more convenient. Optional color steel enclosure is available to reduce noise and dust pollution, providing an environmentally friendly solution.

Project Cases

Established in 1991, Jin Rui is a professional concrete plant manufacturer with over 30 years of industry experience. From stationary concrete plants to integrated concrete plants, our concrete equipment serves various construction projects of high-speed railways, bridges, and airports, delivering reliable concrete production solutions tailored to different construction cycles and site conditions.

Get professional advice for your project - contact our experts today.