HZN-Z Series

Precast Concrete Batching Plant

Compact concrete batch plant configured with planetary concrete mixer and skip hoist feeding for small-to-medium precast factories with limited spaces

- Production Capacity 35–75 m³/h

- Plant Configuration Compact structure with planetary mixer for high uniformity

The combined concrete batching plant integrates a JN-AH skip-hoist vertical shaft planetary mixer with HP series aggregate batching machines, offering both cumulative and individual weighing options. The plant can be configured with dedicated weighing modules for cement, mineral additives, water, and chemical admixtures, alongside a complete air supply system. With a centralized control system, the entire mixing process is completed automatically, with manual switching available to support both automatic and semi-automatic production modes.

This batching plant features a compact structure, small footprint, and stable, reliable performance. It is suitable for mixing dry, semi-dry, high-performance, and high-strength concrete. The mixer can be configured with two discharge gates according to production line requirements, allowing one mixer to supply multiple production lines. It is widely used in block production, pipe pile manufacturing, PC component production, and special high-performance concrete mixing applications.

Technical Parameters

| Model | |

|

|

| Theoretical capacity (m³/h) | 35 | 50 | 75 |

| Mixer model | JN750AH | JN1000AH | JN1500AH |

| Mixer motor power (kW) | 30 | 37 | 55 |

| Charging capacity (L) | 1125 | 1500 | 2250 |

| Discharging capacity (L) | 750 | 1000 | 1500 |

| Max. aggregate size (crushed stone/pebble) (mm) | ≤60 | ≤60 | ≤80 |

| Hoist motor power (kW) | 7.5 | 11 | 18.5 |

| Feeding mode | Skip hoist | Skip hoist | Skip hoist |

| Screw conveyor model | LSY219 | LSY219 | LSY273/LSY219 |

| Aggregate batching machine model | HP1200 | HP1600 | HP2400 |

| Aggregate weighing accuracy | ±2% | ±2% | ±2% |

| Cement weighing accuracy | ±1% | ±1% | ±1% |

| Mineral additive weighing accuracy | ±1% | ±1% | ±1% |

| Water weighing accuracy | ±1% | ±1% | ±1% |

| Admixture weighing accuracy | ±1% | ±1% | ±1% |

| Approx. total power (excluding screw conveyor, kW) | 60 | 75 | 105 |

| Discharge height | 2.2m standard/raised height for mixer truck loading/customized height | ||

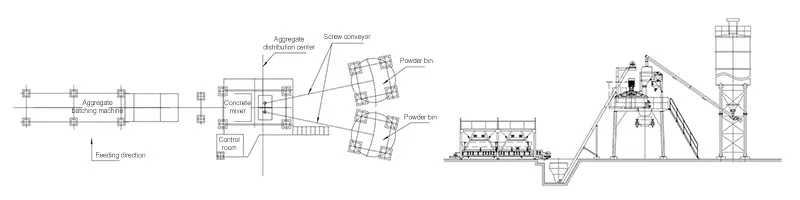

Process Flow

Main Components

Concrete Mixer

JN-AH series concrete mixer is a vertical shaft planetary mixer equipped with skip hoist, featuring an electric winch for material loading. Its compact structure ensures a small footprint and easy installation, while the planetary mixing action delivers superior homogeneity. To meet diverse production line needs, the concrete mixer can be configured with two discharge gates, allowing a single mixer to serve multiple production lines simultaneously.

Aggregate Batching Machine

HP series aggregate batching machines adopt sectional assembled bin panels for easy installation. Pneumatic batching ensures fast and accurate dosing, while belt discharge enables clean and rapid unloading. Both cumulative and individual weighing types are available to meet different batching requirements. Suitable for concrete construction sites, commercial concrete batching plants, and precast concrete factories.

Screw Conveyor

The cement screw conveyor features a housing made of high-quality steel pipes. Each section is connected by flanges. The conveying screw adopts a variable-pitch blade design, allowing smooth and stable powder material conveying.

Weighing System

The weighing system is equipped with high-precision load cells to ensure consistent and accurate measurement.

For material release, it utilizes pneumatically operated butterfly valves of premium quality, providing rapid actuation and a hermetic seal to prevent leakage.

Project Cases

Established in 1991, Jin Rui is a professional concrete plant manufacturer with over 30 years of industry experience. From stationary concrete plants to integrated concrete plants, our concrete equipment serves various construction projects of high-speed railways, bridges, and airports, delivering reliable concrete production solutions tailored to different construction cycles and site conditions.

Get professional advice for your project - contact our experts today.