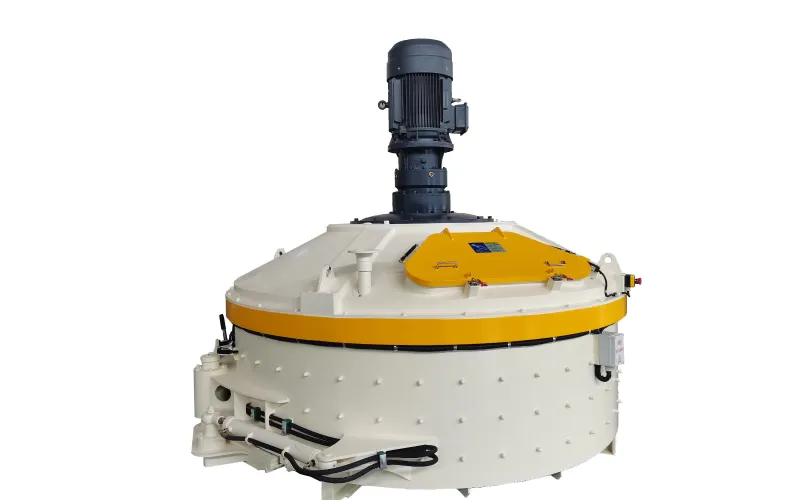

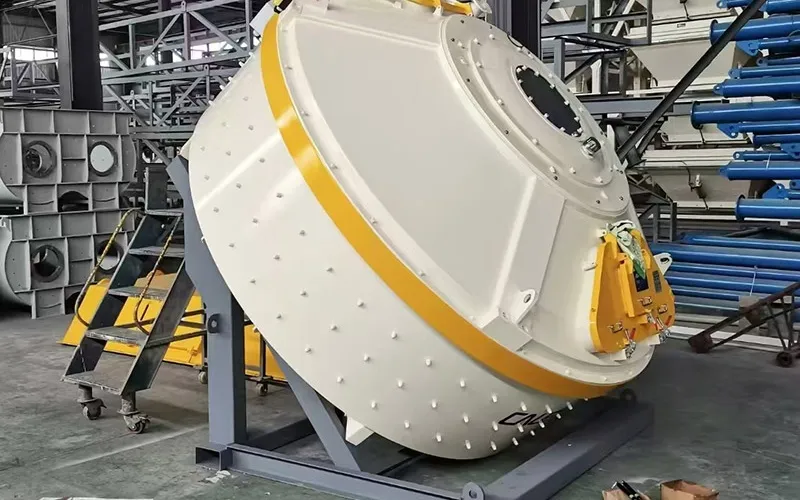

JN Series

Planetary Concrete Mixer, Single-Drive

Vertical shaft mixer for concrete batching plants

- Discharge Capacity 0.5 – 1.0 m³ / batch

- Drive Efficiency Efficient single-motor design for easy maintenance

The small vertical shaft planetary concrete mixer adopts a hydraulic discharge system, ensuring smooth opening and closing of the discharge gate with high thrust and low risk of material jamming. The number of discharge gates can be configured as one or two according to customer requirements. The mixing system combines revolution and rotation in a planetary mixing pattern, achieving more uniform material mixing while eliminating shaft-end slurry leakage issues in the transmission system.

With a compact structure and excellent performance, this mixer is well suited for precast industries such as block production, pipe piles, and PC components.

Technical Parameters

| Model | |

|

|

|

|

| Feed capacity (L) | 525 | 750 | 1125 | 1500 | 2250 |

| Discharge capacity (L) | 350 | 500 | 750 | 1000 | 5000 |

| Theoretical productivity (m³/h) | 20 | 30 | 45 | 60 | 90 |

| Mixing motor power (kW) | 15 | 18.5 | 30 | 37 | 55 |

| Max. aggregate size (mm) | ≤40 | ≤60 | ≤60 | ≤60 | ≤80 |

| Number of mixing blades | 1×2 | 1×2 | 1×2/2×2 | 2×2 | 2×2 |

| Number of scrapers | 2 | 2 | 3/2 | 2 | 2 |

| Overall dimensions (L×W×H, mm, single door) | 1920×2050×2240 | 2200×2250×2280 | 2600×2430×2360 | 2900×2610×2660 | 3150×2870×2800 |

| Overall dimensions (L×W×H, mm, double door) | 2200×2050×2240 | 2480×2250×2280 | 2860×2430×2360 | 3100×2610×2660 | 3420×2870×2800 |

| Machine weight (kg) | 2200 | 2600 | 4600/4800 | 6300 | 7500 |

Main Components

Gear Reducer

The small vertical shaft planetary concrete mixer adopts a single-motor drive configuration, combined with a high-performance reducer and motor. This design ensures smooth operation, low noise, high output torque, and long service life.

Mixing System

Wear parts of the mixing system are made of wear-resistant high-chromium alloy cast iron, significantly extending service life.

Discharge Gates

A patented adjustable discharge gate design provides excellent sealing performance while reducing seal wear. The hydraulic discharge system allows smooth operation, with up to three discharge gates available according to requirements.

Safety Switches

A contact limit switch is installed on the top cover inspection door. When the door is opened, the main motor stops automatically to protect maintenance personnel. A key-operated safety switch is also provided on the mixer body for emergency stop and maintenance. Removing the key prevents accidental operation.

Water Supply System

The water supply system uses multi-angle spray nozzles to ensure uniform water distribution, enabling faster and more uniform mixing.

Established in 1991, Jin Rui is a professional concrete plant manufacturer with over 30 years of industry experience. From stationary concrete plants to integrated concrete plants, our concrete equipment serves various construction projects of high-speed railways, bridges, and airports, delivering reliable concrete production solutions tailored to different construction cycles and site conditions.

Get professional advice for your project - contact our experts today.